| What do shock absorbers do |

|

Essentially, shock absorbers do two things. Apart from controlling

the movement of springs and suspension, shock absorbers also keep your

tyres in contact with the ground at all times. At rest or in motion, the

bottom surface of your tyres is the only part of your vehicle in contact

with the road. Any time that a tyre’s contact with the ground is broken

or reduced, your ability to drive, steer and brake is severely

compromised.

Despite popular belief, shock absorbers do not support the weight of

a vehicle.

|

|

| Types of Shock

Absorber |

|

Although all shock absorbers do the same job, different types of

vehicles and suspension designs require different types of shock

absorbers which can appear radically different.

No matter the application, all shock absorbers fit into one of three

broadly defined types – conventional telescopic shock absorbers, struts

or spring seat shocks

|

| Conventional telescopic

shock absorbers |

| This is the simplest type of shock absorber and is generally

replaced rather than repaired. This type of shock absorber can be found

on both front and rear suspension systems and is relatively inexpensive |

| |

| Strut type shock absorbers |

| Although they do the same basic job, struts replace part of the

suspension system and must be more ruggedly built to cope with greater

loads and forces. Although most commonly seen on the front and rear of

small to medium cars, larger cars are now tending towards strut based

suspension design. The strut category is further divided into sealed and

repairable units. As the name suggests, sealed units are designed to be

fully replaced, whilst repairable (McPherson) struts are able to be

fitted with replacement strut cartridges |

| |

| Spring seat shocks |

| The spring seat type shows characteristics of both telescopic and

strut type shock absorbers. Like struts, a spring seat shock is a

suspension unit and damping device in a single unit. Unlike struts

however, they are not designed to be subject to high side loads. Built

using similar components to conventional shock absorbers, spring seat

shocks are also sealed requiring full replacement. |

|

| |

| Mechanism |

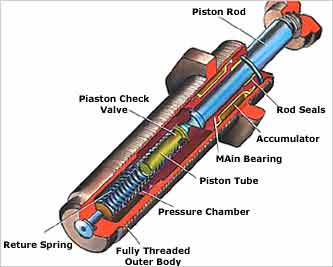

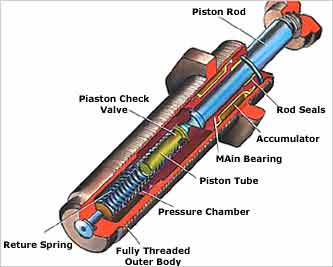

Shock absorber are attached at the end of the piston rod and works

against hydraulic fluid in the pressure tube. The movement of the

suspension up and down force the hydraulic fluid through minute holes

inside the piston. However only small amount of fluid is forced inside

the piston. The insertion of fluid reduce the speed of the piston which

in turn slows down the piston, which in turn slows down spring and

suspension movement.

The speed of the suspension and the number and size of the orifices in

the piston determines the resistance a shock absorber. Nowadays, shock

absorbers are made using this principle. That is faster movement of

suspension means more resistance shock absorber provides. Shock absorber

designed on this basis simply reduces the bounce, Roll or sway and Brake

dive and Acceleration squat. |

| |

| Shock Absorber Working

Principle |

|

There are two cycles in which Shock absorber works: |

| |

| Compression Cycle |

In the compression cycle the piston moves downward and compresses the

hydraulic fluid in the chamber which is situated below the piston. In

this cycle or downward movement, the fluid flows to upper chamber from

down chamber through piston. Some of the fluid also flows into reserve

tube

through the compression valve. Flow is controlled by valves in the

piston and in the compression valve. |

| |

| Extension cycle

|

|

In the extension cycle the piston moves upwards toward the top of the

pressure tube. The upward movement results in the compressing of the

fluid in the chamber lying above the piston. The extension cycle

generally provides more resistance than compression cycle. |

| |